Our unique product, SARCON is an advanced silicone rubber with high thermal conductivity and superior flame retardancy.

SARCON's versatility in thermal management applications is doubly enhanced by way of the variety of end-use configurations possible, and the many standard material formulations available in each. The silicone rubber-based materials offer other useful elements such as electrical insulation, protective coverings, and gasketing as integral features in most designs.

Along with a few simple recommendations to help obtain the optimum performance for your application, a few suggestions are included which may help you take advantage of some of these other features.

SARCON Product Series

As shown below, even the most highly polished mating surfaces do not make reliable contact surfaces. Complete physical contact is necessary to minimize the resistance to heat flow for the best thermally conductive path. Such surface voids, when properly filled with a conformable, SARCON, will in most cases exhibit the continuous characteristics of a solid metal of the same dimensions.

Thermal resistance of semiconductor mounted to substrate is appreciably increased at junction of porous surfaces.

Thermal resistance of semiconductor mounted to substrate with gap filler pad is eliminated yielding higher temperature gradient.

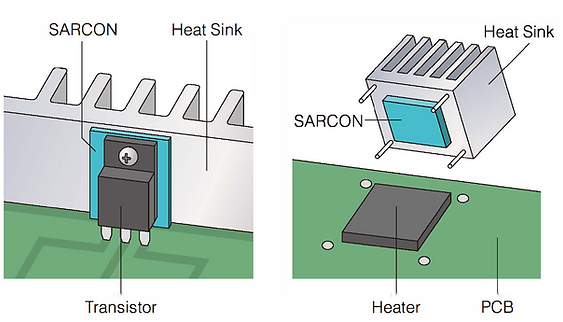

SARCON Applications

SARCON has been used for many years in Automobile, Telecommunication Equipment, Consumer and Industrial Equipment.

Welcome to Fujipoly America®, your trusted source for high-quality thermal interface materials for the automotive industry. Our products are designed to help you achieve optimal thermal management in your automotive applications, ensuring reliable performance and long-lasting durability.

Thermal interface materials are essential components in the automotive industry, as they help to transfer heat away from critical components such as engines, transmissions, and power electronics. Without proper thermal management, these components can overheat and fail, leading to costly repairs and downtime.

At Fujipoly America®, we offer a wide range of thermal interface materials that are specifically designed for use in the automotive industry. Our products are engineered to provide superior thermal conductivity, excellent electrical insulation, and exceptional durability, making them ideal for use in a variety of automotive applications.

Whether you are looking for thermal interface materials for engine cooling systems, transmission systems, or power electronics, we have the products you need to ensure reliable performance and long-lasting durability. Our team of experts can help you select the right materials for your specific application, ensuring that you get the best possible results.

So why choose Fujipoly America® for your thermal interface material needs? Here are just a few reasons:

High-quality products:

Our thermal interface materials are made from the highest-quality materials, ensuring superior performance and long-lasting durability.

Expert support:

Our team of experts can help you select the right materials for your specific application, ensuring that you get the best possible results.

Competitive pricing:

We offer competitive pricing on all of our products, making it easy to get the thermal interface materials you need without breaking the bank.

Fast shipping:

We offer fast shipping on all of our products, ensuring that you get the materials you need when you need them.

So if you are looking for high-quality thermal interface materials for the automotive industry, look no further than Fujipoly America®. Contact us today to learn more about our products and how we can help you achieve optimal thermal management in your automotive applications.

-

Lithium-ion Battery

-

Camera

-

LED Head Lamp

-

Infotainment

-

General ECU

-

Power Steering

-

Brake Lamps

-

EV Battery Packs

-

Fuel Cells

-

Inverters